Key Takeaways:

- Injection molding is a preferred choice for producing parts and products in various industries due to its efficiency, reliability, and cost-effectiveness.

- Injection molding solution companies specialize in providing comprehensive solutions for injection molding projects, helping clients optimize production processes and improve product quality.

- Injection molding solutions have revolutionized industries such as automotive, medical, consumer electronics, and packaging.

- Criteria for selecting top injection molding solution companies include innovation, technological advancements, quality control, customer satisfaction, and positive reviews.

- The top injection molding solution companies to watch out for are Company A, Company B, and Company C.

- Success stories and case studies highlight how injection molding solution companies enhance product design, achieve cost savings, and overcome manufacturing complexities.

Introduction to Injection Molding Solution Companies

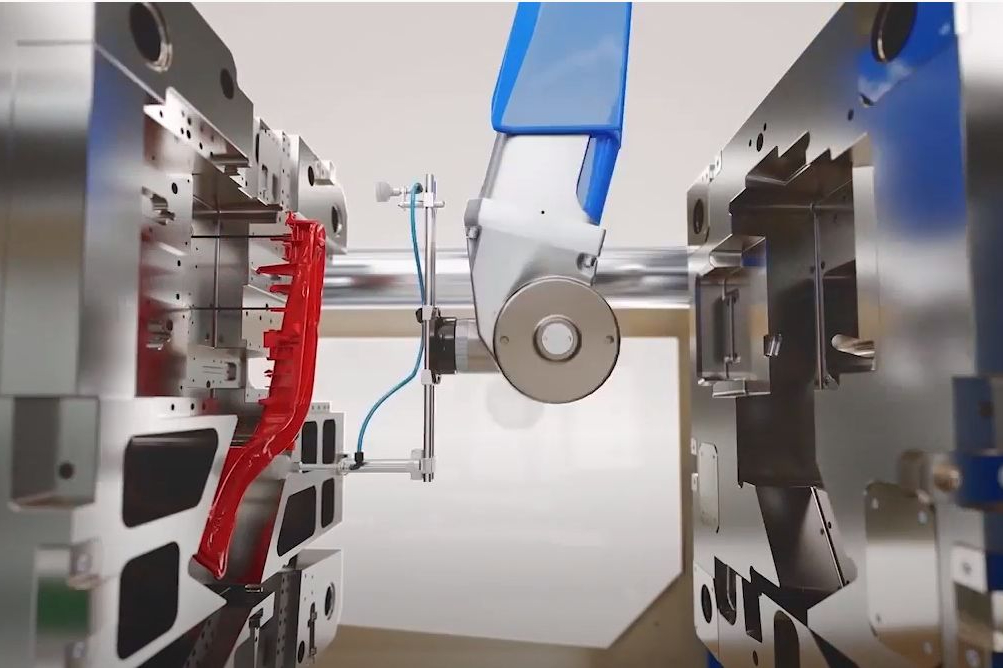

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create complex shapes. It is a preferred choice for producing parts and products in various industries due to its efficiency, reliability, and cost-effectiveness. However, to leverage the full potential of injection molding, companies often need the expertise and capabilities offered by injection molding solution providers.

Understanding the Role of Injection Molding in Manufacturing

Injection molding plays a crucial role in the manufacturing industry. It enables the production of intricate and precise components that would be challenging or impossible to manufacture using other methods. The process involves injecting molten material, such as plastic or metal, into a mold under high pressure. Once the material cools and solidifies, the mold is opened, and the finished product is ejected.

Injection molding offers several advantages over alternative manufacturing processes. It allows for high-volume production, reducing per-unit costs and enabling economies of scale. The process is also highly repeatable and scalable, ensuring consistent quality across large production runs. Furthermore, injection molding offers design flexibility, with the ability to produce complex geometries, intricate details, and integrated features.

The Growing Importance of Injection Molding Solution Companies

Injection molding solution companies have become increasingly important in today’s manufacturing landscape. These companies specialize in providing comprehensive solutions for injection molding projects, helping their clients optimize production processes, improve product quality, and achieve cost savings.

Injection molding solution companies offer expertise in tooling design and manufacturing, material selection, process optimization, and quality control. They leverage their knowledge and experience to guide clients through every step of the injection molding process, from initial design consultation to final product delivery.

With the rapid advancement of technology and increasing demands for high-quality products, injection molding solution companies play a vital role in helping manufacturers stay competitive in their respective industries. By collaborating with these solution providers, companies can benefit from their specialized knowledge, state-of-the-art equipment, and innovative approaches to injection molding.

How Injection Molding Solutions Have Revolutionized Various Industries

Injection molding solutions have had a transformative impact on numerous industries, enabling advancements in product design, production efficiency, and overall manufacturing capabilities.

In the automotive industry, injection molding solutions have revolutionized the production of interior and exterior components, such as bumpers, dashboards, and door panels. The ability to create complex shapes, incorporate multiple materials, and achieve precise tolerances has led to improved aesthetics, functionality, and durability of automotive parts.

In the medical field, injection molding has facilitated the production of high-quality medical devices, such as syringes, valves, and implants. The exceptional accuracy and consistency of injection molding have allowed for tight tolerances and enhanced safety in medical applications.

Consumer electronics and appliance manufacturers have also benefited from injection molding solutions. The process enables the production of lightweight, yet robust components used in devices like smartphones, laptops, and kitchen appliances. Injection molding allows for the integration of intricate features, such as buttons, connectors, and hinges, resulting in sleek and functional products.

Furthermore, injection molding has played a crucial role in the packaging industry by enabling the efficient production of plastic containers, caps, and closures. The process allows for high-speed, high-volume manufacturing, reducing costs and ensuring product consistency.

Criteria for Selecting the Top Injection Molding Solution Companies

Choosing the right injection molding solution company is essential for a successful project outcome. Several key criteria should be considered when evaluating these companies:

Innovation and Technological Advancements in Injection Molding

The top injection molding solution companies are at the forefront of innovation and continuously invest in research and development. They leverage the latest technologies and techniques to improve process efficiency, enhance product quality, and expand the capabilities of injection molding.

These companies stay up-to-date with advancements in materials, tooling, automation, and software systems. They embrace technologies like 3D printing, computer-aided design (CAD), and simulation software to optimize part design, tooling development, and production processes.

Quality Control and Assurance in Injection Molding Solutions

Injecting molding solution companies that prioritize quality control and assurance are crucial partners for manufacturers. They implement rigorous quality control measures to ensure that the produced parts meet or exceed the required specifications.

The top companies adhere to internationally recognized quality standards, such as ISO 9001, and employ advanced inspection techniques, such as statistical process control (SPC) and coordinate measuring machines (CMM). They have robust quality management systems in place to track and trace each step of the production process, identifying and addressing any potential issues promptly.

Customer Satisfaction and Positive Reviews as Key Factors

Customer satisfaction and positive reviews are strong indicators of a top-notch injection molding solution company. These companies prioritize building strong relationships with their clients and focus on delivering exceptional customer service.

It is essential to assess the track record of the company by reviewing customer testimonials, case studies, and references. By understanding the experiences of past clients, it becomes easier to evaluate the company’s ability to meet project requirements, adhere to deadlines, and provide ongoing support and collaboration.

The Top Injection Molding Solution Companies to Watch Out For

Company A: Pioneering the Future of Injection Molding

Company A is a leading injection molding solution provider known for its cutting-edge technologies and innovative solutions. They have a team of experienced engineers and designers who collaborate closely with clients to develop tailored solutions for their specific needs.

The company specializes in precision molding, offering tight tolerances and exceptional part quality. They utilize advanced molding techniques and state-of-the-art machinery to produce complex components with superior functionality. Company A also emphasizes sustainability by incorporating eco-friendly materials and energy-efficient processes into their solutions.

Company B: Redefining Efficiency and Precision in Injection Molding

Company B stands out for its commitment to efficiency and precision in injection molding. They have implemented advanced automation systems and robotics that streamline the production process and minimize human error.

The company’s expertise lies in high-volume production, with the capability to meet demanding production schedules without compromising quality. They have a strong focus on continuous improvement and employ lean manufacturing principles to optimize workflow and minimize waste. Company B’s dedication to excellence has earned them a reputation for delivering products of the highest quality.

Company C: Delivering Next-Level Customization in Injection Molding Solutions

Company C specializes in providing customized injection molding solutions to meet the unique requirements of each client. They have extensive experience in producing complex, multi-component parts and excel in overmolding and insert molding.

The company leverages advanced software systems and simulation tools to optimize part design and validate the manufacturability of custom components. Their commitment to customization extends to material selection, color matching, and surface finishes, ensuring that the final products meet the clients’ aesthetic and functional expectations.

Success Stories and Case Studies: How Injection Molding Solution Companies Make a Difference

Case Study 1: Enhancing Product Design and Functionality through Injection Molding

Company A collaborated with a consumer electronics company to enhance the design and functionality of their flagship smartphone. By leveraging their expertise in injection molding, Company A helped the client develop a sleek and durable phone body with integrated buttons and connectors.

The injection molding process allowed for the production of complex geometries and precise details, resulting in an appealing and ergonomic design. The client achieved significant cost savings through high-volume production, and the final product received rave reviews for its aesthetics and user experience.

Case Study 2: Achieving Cost Savings and Faster Time-to-Market with Injection Molding Solutions

Company B partnered with an automotive manufacturer to optimize the production of a critical engine component. Through careful analysis and process optimization, Company B reduced cycle times and material waste, resulting in substantial cost savings for the client.

Their expertise in tooling design and material selection enabled the production of high-quality parts with tight tolerances. The improved production efficiency also led to a shorter time-to-market, allowing the automotive manufacturer to meet customer demands and gain a competitive edge in the market.

Case Study 3: Overcoming Complexities and Achieving Manufacturing Excellence with Injection Molding

Company C worked with a medical device manufacturer to develop a complex implant used in orthopedic surgeries. The project involved overmolding multiple biomaterials and ensuring precise alignment between different components.

Through advanced mold design and simulation, Company C successfully achieved the desired functionality and aesthetics of the implant. Their expertise in overmolding allowed for the integration of different materials, enhancing the durability and biocompatibility of the final product. The collaboration resulted in a groundbreaking implant design that significantly improved patient outcomes.

FAQ

Question: What is injection molding? – Injection molding is a manufacturing process that involves injecting molten material into a mold to create complex shapes. It is preferred for its efficiency, reliability, and cost-effectiveness.

Question: What do injection molding solution companies do? – Injection molding solution companies provide comprehensive solutions for injection molding projects. They specialize in tooling design, material selection, process optimization, and quality control to help clients optimize production processes, improve product quality, and achieve cost savings.

Question: How has injection molding revolutionized industries? – Injection molding solutions have revolutionized various industries such as automotive, medical, consumer electronics, and packaging. They have enabled advancements in product design, production efficiency, and overall manufacturing capabilities.

Question: What criteria should be considered when selecting injection molding solution companies? – When selecting injection molding solution companies, it is important to consider criteria such as innovation, technological advancements, quality control, customer satisfaction, and positive reviews.

Question: What role does innovation play in injection molding solutions? – The top injection molding solution companies prioritize innovation and invest in research and development. They leverage the latest technologies and techniques to improve process efficiency, enhance product quality, and expand the capabilities of injection molding.

Question: How do injection molding solution companies ensure quality control? – Top injection molding solution companies implement rigorous quality control measures, adhere to internationally recognized quality standards, and employ advanced inspection techniques. They have robust quality management systems in place to track and trace each step of the production process.

Question: How important is customer satisfaction in selecting injection molding solution companies? – Customer satisfaction and positive reviews are key factors to consider when selecting an injection molding solution company. It is important to review customer testimonials, case studies, and references to assess the company’s track record in meeting project requirements and providing exceptional customer service.

Question: Can you provide examples of top injection molding solution companies? – Some top injection molding solution companies to watch out for are Company A, Company B, and Company C. Each company has unique specialties and expertise in injection molding.