Enter the impingement freezer—a cutting-edge solution that is transforming the way industries approach freezing and cooling processes. At Industrialfreezing.com, we understand the critical role that advanced freezing technology plays in your operations, and the impingement freezer stands out as a game-changer in this arena.

Understanding impingement freezing technology

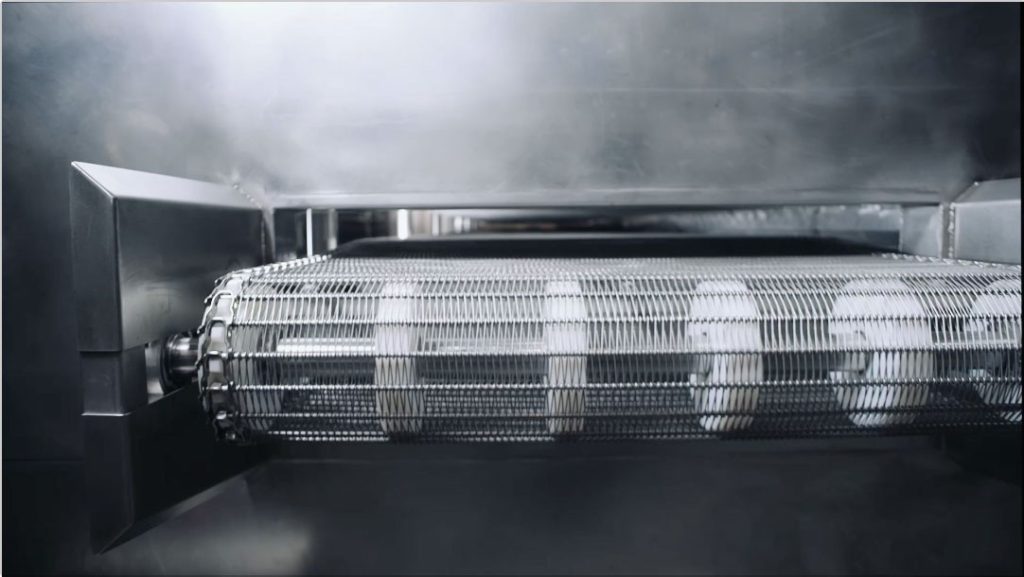

Impingement freezing harnesses the principles of impingement heat transfer to achieve rapid and uniform cooling of products. Unlike traditional freezing methods that rely on ambient air or slower cooling mediums, impingement freezers use high-velocity coolant jets directed precisely onto the surface of the product. This targeted approach maximizes heat transfer efficiency, ensuring that products are frozen quickly and uniformly.

The core mechanism involves the strategic placement of nozzles that emit a controlled flow of coolant, such as liquid nitrogen or refrigerants, directly onto the product’s surface. This method disrupts the boundary layer of air that typically slows down heat exchange, allowing for more effective and faster cooling. The result is a significant reduction in freezing times, which is essential for preserving the structural integrity and quality of temperature-sensitive products.

Benefits for industrial operations

Implementing impingement freezer technology offers a myriad of benefits tailored to meet the demands of industrial applications. One of the most notable advantages is the drastic reduction in processing time. Traditional freezing methods can be time-consuming, leading to potential bottlenecks in production lines. Impingement freezers, with their rapid cooling capabilities, streamline the freezing process, enhancing overall operational efficiency.

Moreover, the uniformity of freezing achieved through impingement technology minimizes the risk of product deformation or degradation. In industries such as food processing, where texture and structural integrity are vital, this uniformity ensures that products maintain their desired qualities post-freezing. Similarly, in pharmaceutical manufacturing, precise temperature control is essential for preserving the efficacy of sensitive compounds, making impingement freezers an invaluable asset.

Energy efficiency is another critical consideration for industrial operations. Impingement freezers are designed to optimize energy usage by maximizing heat transfer while minimizing energy consumption. This not only reduces operational costs but also aligns with sustainable practices, an increasingly important factor for modern businesses aiming to reduce their environmental footprint.

Customization and versatility

One of the standout features of impingement freezers is their adaptability to various industrial needs. At Industrialfreezing.com, we recognize that each industry has unique requirements, and our impingement freezer solutions are highly customizable to accommodate different product types, sizes, and freezing specifications. Whether you’re dealing with delicate food items, large pharmaceutical batches, or intricate manufacturing components, impingement freezers can be tailored to meet your specific needs.

The versatility of impingement freezing technology extends to its scalability. From small-scale operations to large industrial facilities, impingement freezers can be scaled to fit the volume and throughput demands of your business. This flexibility ensures that as your operations grow, your freezing solutions can seamlessly adapt to support increased production without compromising on performance or efficiency.

Enhancing product quality and safety

In today’s competitive market, maintaining high product quality and safety standards is non-negotiable. Impingement freezers play a pivotal role in achieving these standards by providing precise temperature control and rapid cooling. Consistent freezing not only preserves the quality and freshness of products but also extends their shelf life, offering significant value to both producers and consumers.

For industries where regulatory compliance is critical, impingement freezers offer the reliability needed to meet stringent safety standards. By ensuring that products are frozen uniformly and quickly, these freezers help in preventing the growth of harmful microorganisms and preserving the integrity of sensitive materials. This level of control is essential for maintaining compliance with industry regulations and safeguarding consumer trust.

Embrace the future of freezing with Industrialfreezing.com

As industries continue to evolve, the demand for advanced and efficient freezing solutions grows. Impingement freezers represent the forefront of freezing technology, offering unparalleled efficiency, precision, and versatility. At Industrialfreezing.com, we are committed to providing our customers with state-of-the-art freezing systems that enhance operational performance and ensure the highest standards of product quality and safety.

Investing in an impingement freezer is not just a step towards modernizing your freezing processes; it’s a strategic move to stay ahead in a competitive landscape. Embrace the future of industrial freezing with impingement technology and experience the transformative benefits it brings to your business.